For several years, the Institute of Materials Science (ifm) at Hof University of Applied Sciences has been researching the development of motion-flexible vascular prostheses for medical technology. At the university campus in Münchberg, the novel stents are being woven for the first time from suitable materials in their application size. Two projects funded by the German Federal Ministry for Economic Affairs and Energy as part of the Knowledge and Technology Transfer Program (WIPANO) are now entering the decisive phase. The aim of the support from the federal government is in particular to further develop the innovations through to practical use on the market

“GeVeS – Braided Branched Structures for Use in Medical Technology and Pipe Rehabilitation” and “KISS – Knospendes Implantierverfahren für Stentstrukturen” – the names for the current projects sound as complex as the research field is. There is no doubt that product development for medical use on humans is one of the greatest challenges that can be faced, even in science. This is precisely the case in Münchberg. Both of the funded projects being pursued there tie in with a remarkable invention: Medical stents for constricted vessels, which consist of braided structures, and a corresponding implantation procedure have two industrial property rights there. The next step is to develop the invention further – until it is ready for the market.

Patent protection for braided stents

The Münchberg patent describes and protects the invention of a special braided and branched structure together with an automatically braided transition area, which – as a special feature – is completely free of holes. This hole-free gusset is achieved by additional crossing and twisting of threads among each other, making it particularly durable and robust – a remarkable innovation in this field that has already caused a sensation in the past.

“To improve the structure even further, the use of a larger number of thread systems in the transition area of the branching is currently being researched. This is intended to achieve a further increase in density as well as improved hole closure,” says Prof. Dr. Frank Ficker, head of the Institute of Materials Science.

Expanding fields of application

In general, the researchers at the institute want to significantly optimize the properties of braided stent systems in medical technology through continuous further development and thus, as a consequence, also expand fields of application and market potential

To achieve this, for example, part of the current project work is to produce closed gussets with more than one branch. Up to now, multi-branched stents have – according to the current state of the art – been assembled from several individual stents in complex processes. However, ifm’s development now makes direct use in branched vein systems possible, as the improved hole closure can significantly reduce tissue ingrowth. “In addition, this structure ensures uniform medication for all affected areas of the body, and this has positive consequences for tissue growth and healing,” says Prof. Dr. Frank Ficker.

Stent opens like a flower

For the implantation of such a branched stent, the “KISS” project has now also been able to develop and deepen an innovative procedure for application. In this process, the branched stent made of NiTiNOL (i.e., a nickel-titanium shape memory alloy), which is approved for use inside the body, is inserted into the body in such a way that it only unfolds at its destination like a flower bud. In this way, safe transplantation can be ensured. The advantages are obvious

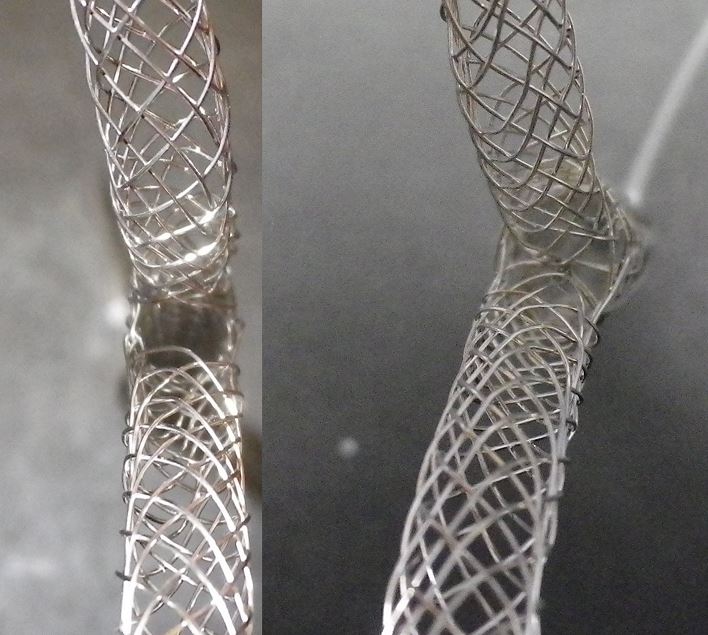

Compared to coronary stents, which according to the state of the art are manufactured using precision laser technology, the braided structures are characterized by a high degree of flexibility in use.”

Prof. Dr. Frank Ficker

“Compared to coronary stents, which according to the state of the art are manufactured using precision laser technology, braided structures are characterized by a high degree of flexibility in use,” said Prof. Dr. Frank Ficker.

Greater flexibility and mobility

Currently, vascular prostheses with a tubular geometry with a straight end are still frequently used in operations, which have to be assembled in the case of branching as described. However, according to surgeons, these are difficult to position, especially with small vessels and tight radii, and due to limited mobility. This problem should be solved by developing branched, braided stents with retractable side arms

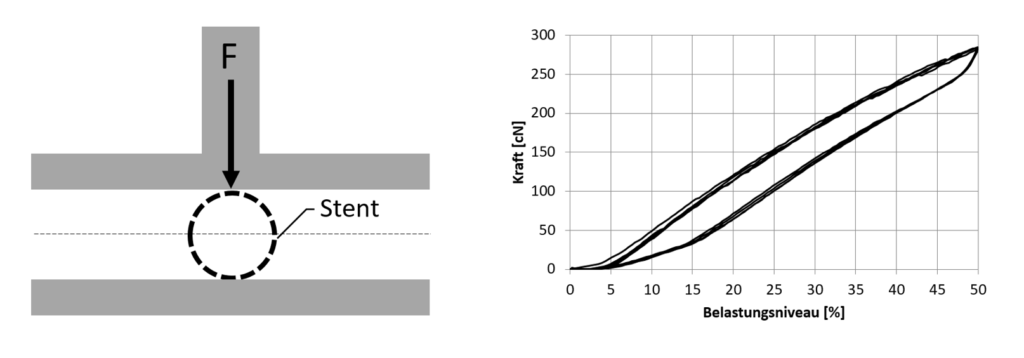

During the research work for the patent application, the theory of the method was only confirmed on a very large scale. In the project, however, it has now been possible to develop stents for coronary vascular bifurcations that are suitable for scale. These now enable researchers and physicians to draw detailed conclusions about subsequent implantation behavior. The stents from Münchberg show high flexibility and superelastic properties

The material springs back into the desired shape after deformation of up to 50% of the load level, thus providing the necessary conditions for successful transplantation.”

Prof. Dr. Frank Ficker