What might air control and cooling elements in the automotive industry look like in 2030? Where should they be installed on the vehicle and what requirements must they fulfill? Students from the Bachelor Design and Mobility program at the Selb learning center dealt with these questions in the summer semester of 2022 as part of a cooperation project with REHAU Automotive. At a recent meeting with Martin Wippermann, responsible for Research & Development Automotive at REHAU Automotive, and his team, the students presented initial ideas together with course director Prof. Lutz Fügener.

The cooperation within the scope of the student project came about on the initiative of REHAU Automotive shortly after the start of the bachelor’s degree program Design and Mobility in the winter semester 2021/2022 and kept the students busy throughout the summer semester. It creates a win-win situation for the still young course of study in Selb and REHAU Automotive in equal measure: The students can apply their theoretical knowledge in practice through an industrial practical project with an automotive focus and gain insights into the working worlds of the attractive regional employer. REHAU, in turn, benefits from the design studies on product innovations with regard to its “Functional Polymer Systems” strategy.

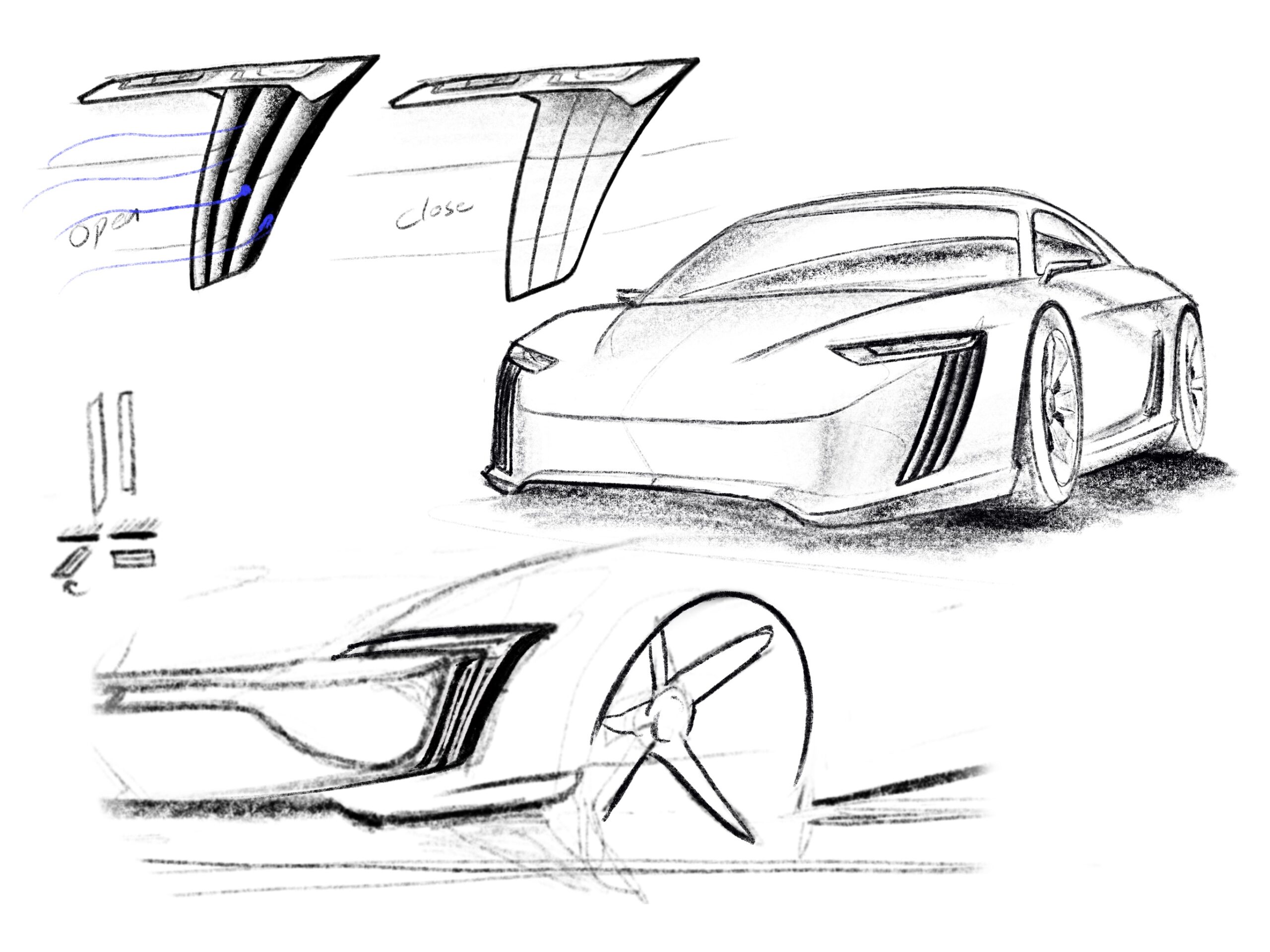

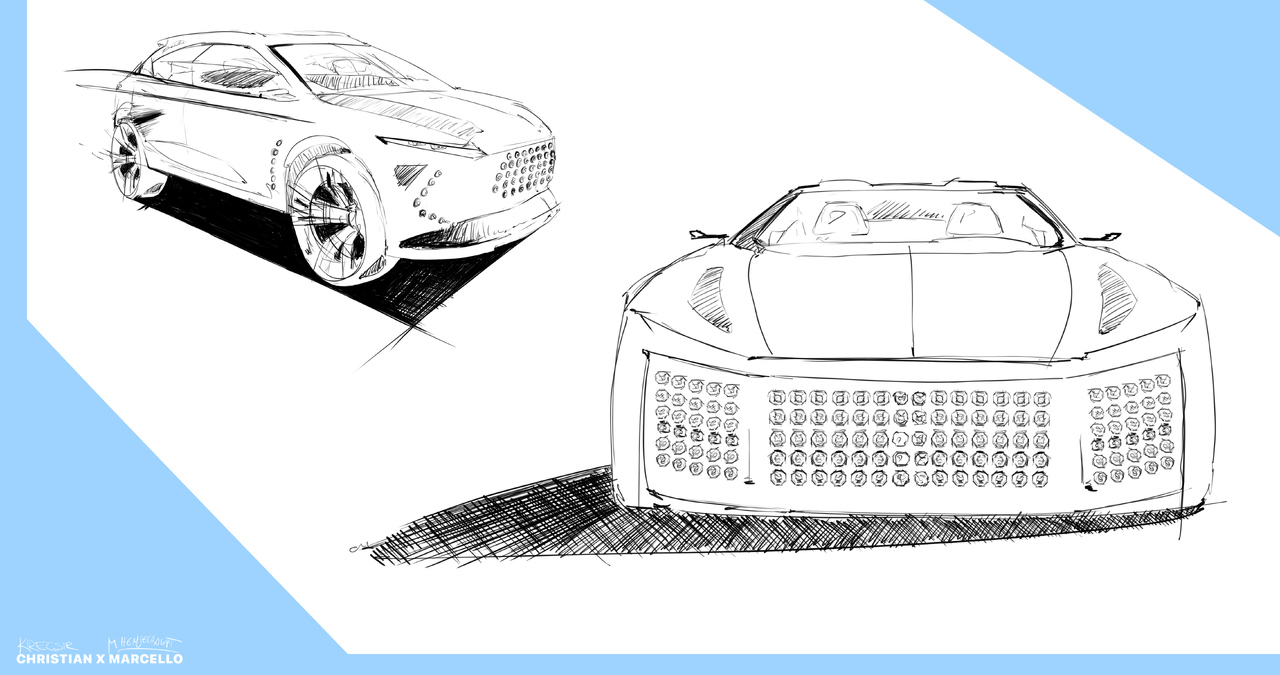

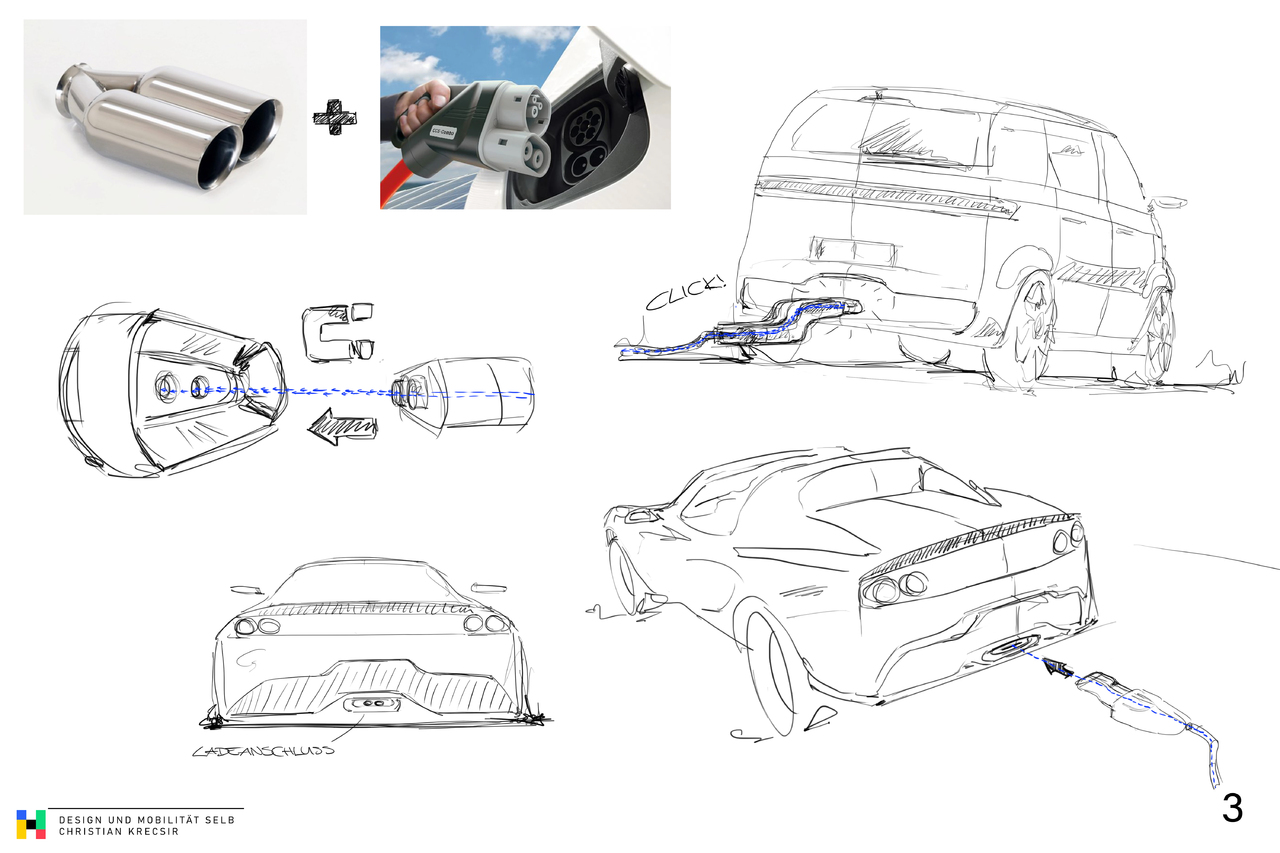

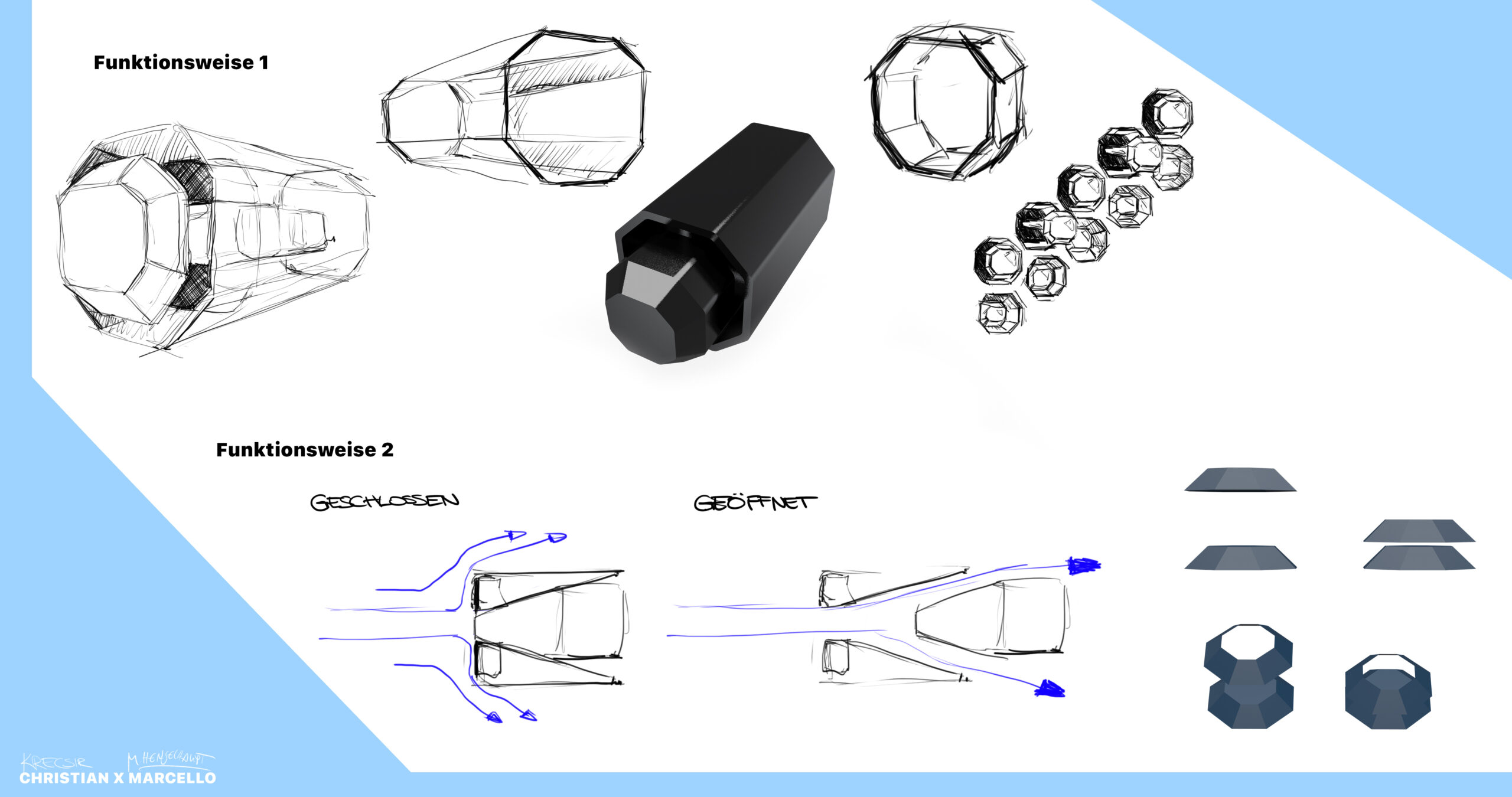

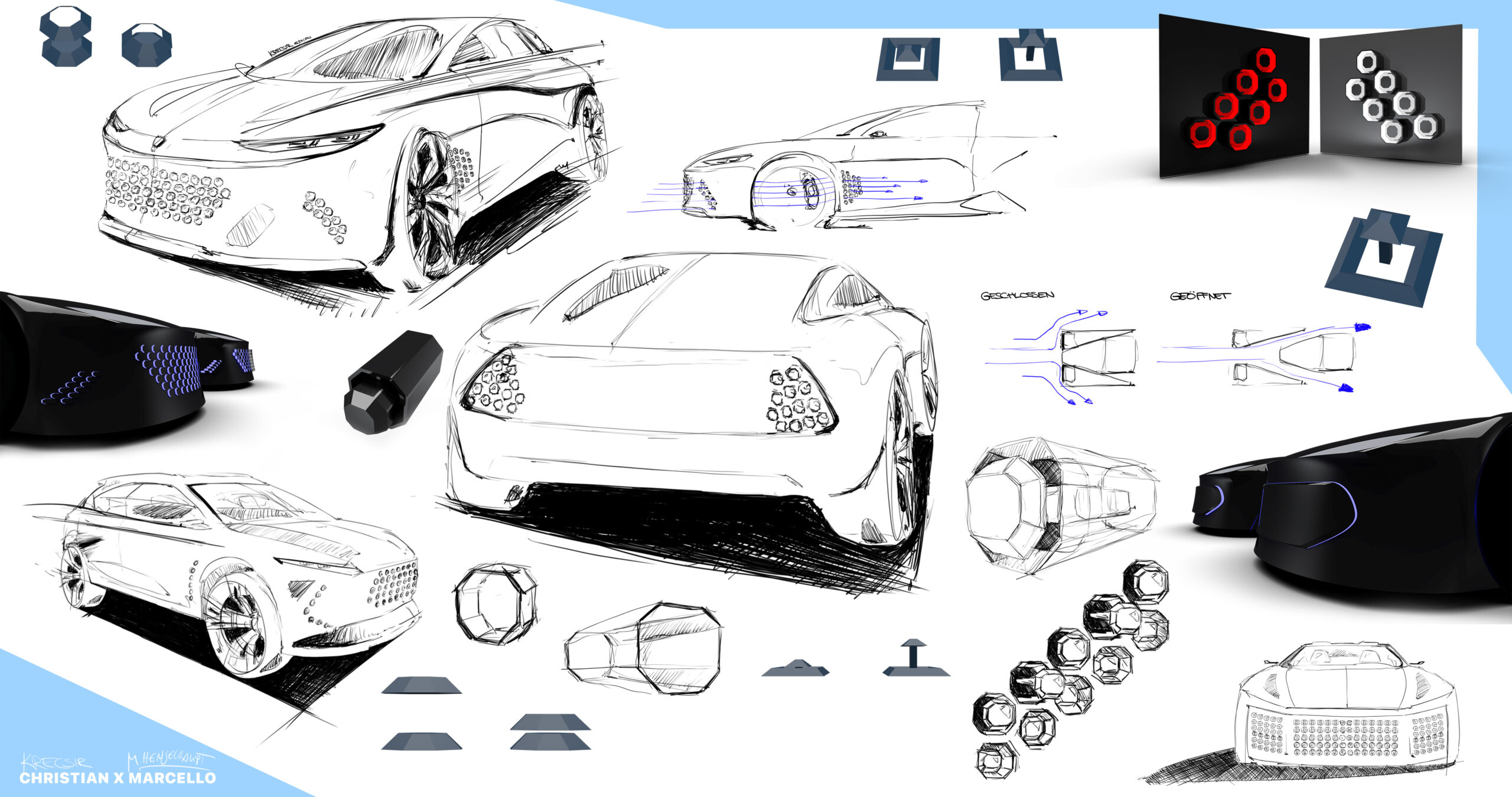

From honeycombs to gills and salt shakers to magnetic closures, the project teams found a wide variety of creative design forms and functionalities for future air ducting systems and cooling elements for automotive production. A wide variety of materials, from plastics to textiles, were used. During the presentation of their designs in the Spiegelhaus Selb in front of a REHAU expert panel, the experts were impressed by the professionalism of the students’ presentations and discussed with them questions regarding technical feasibility.

Prof. Lutz Fügener assessed the practical relevance of the cooperation as particularly valuable: “Thanks to this project, the students can not only put design ideas on paper, but also directly test their feasibility in reality. This practical reference helps us a lot,” emphasizes the design professional, who heads the Bachelor Design and Mobility.

Martin Wippermann also sees many opportunities in the cooperation project: “We combine the students’ ideas with ours and derive approaches from them, which we discuss together with the car manufacturers.” For the customer, he says, it is important to clearly highlight the benefits of the innovations. Only if this is visible and convincing can higher costs, which are often associated with the use of new materials, be justified.

Before the end of the semester, the project included a visit to the Lower Bavarian automotive plant in Viechtach. Live on site, the students gained an insight into automotive production and manufacturing processes. The students were very happy about this and said that the knowledge would help as a basis for the theory in the next semester.

The milestones of the cooperation project with REHAU Automotive at a glance:

- Start and assignment of tasks to the students by REHAU Automotive (start of summer semester)

- Concept design phase: The design students developed designs based on various tasks (approx. 1-2 weeks)

- Pitch or interim presentation of the design concepts on the premises of Hof University of Applied Sciences at the Selb site in front of a REHAU expert panel

- Evaluation and ranking of the concepts according to supplier-specific industrial evaluation criteria (REHAU internal expert panel) (approx. 1 week)

- Extensive feedback discussion with different REHAU experts and the students on their designs; deepening of the task and team constellations of the students

- Refinement of the design concepts by the students in the teams (approx. 1-2 weeks)

- Final presentation by the students in the Spiegelhaus in Selb

- Practical immersion and excursion to a REHAU Automotive Exterior plant for bumpers in Viechtach

About the bachelor’s degree program in design and mobility:

The bachelor’s degree program in Design and Mobility in cooperation with the Technical College for Product Design at the Selb learning center strives to find new answers to one of mankind’s basic needs: mobility.

The declared aim of the course is to train young designers who want to face the design and technical challenges of future mobility in their professional lives. Thematically, the study contents span a wide range from classic means of transport such as the automobile, the muscle- and motor-driven two- and three-wheeler, air and water vehicles, to the broad field of new forms of mobility tools and their intermodality, to concepts for the transformation of infrastructures and scenarios of mobile life.

The course is designed to train and apply various points of contact between design and engineering. To this end, students take both design and engineering subjects. Graduates should be able to communicate and act in an interdisciplinary manner in an industrial environment and in independent work, and thus be able to work creatively and successfully in heterogeneous project teams and make a valuable contribution to shaping the mobility requirements of the future.