Energy storage is one of the key issues for a sustainable energy supply in the future. Thousands of researchers around the world are currently working on this issue. An exciting project is also currently underway at the Münchberg campus of Hof University of Applied Sciences. Here, new types of ice batteries for cooling applications are being researched, which can help to sustainably reduce energy and CO2. They are powered by surplus solar energy.

We talked to Tushar Sharma, research associate at the Institute for Water and Energy Management at Hof University of Applied Sciences (iwe) and Richard Genes, managing director of the cooperation partner Genes Kältetechnik GmbH from Hof.

Mr. Sharma, please give a brief explanation: what exactly is ice storage and what do you want to find out and achieve with your research?

The technology itself has been on the market for decades and a lot of research has been done at the fundamental level. That is, the process of producing ice in the tank through heat exchangers is known in detail. What is new, however

With the concept of an ice battery, we want to market an affordable and energy-efficient alternative to the existing, electrochemical batteries that have been used to store excess solar PV energy. This is obviously an interesting approach for businesses to avoid energy costs and improve their owncarbon footprint.”

Tushar Sharma

My research focuses on maximizing self-consumption of solar PV energy to produce ice in the ice battery. This means optimizing the control system to maximize the utilization of the ice battery to meet the cooling needs of each industry. So far, we have applied the control strategy to 3 different cases, including a bakery and two breweries. The system was modeled in TRNSYS simulation software and the results showed significant energy andCO2 savings.

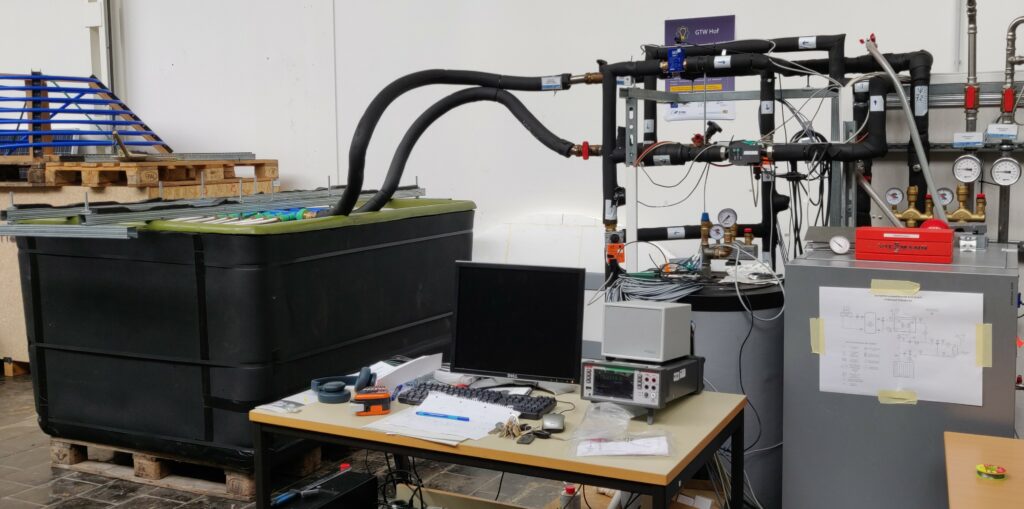

How should you imagine this technically – there is quite an extensive laboratory test stand in Münchberg?

An ice battery is basically just a water storage tank in which heat exchangers are immersed that can form ice by extracting the latent heat energy of the water. In our laboratory at the Münchberg campus, we have experience with various types of heat exchangers, which differ in their appearance. There are star-shaped, spiral-shaped, serpentine-shaped, flat plates and recently also as capillary mats. We have also written a detailed software model for flat plate and capillary mat heat exchangers based on the ice battery.

We are thus able to perform dynamic system simulations and compare the simulation results with experiments performed in the laboratory test rig. Thus, it was found that the capillary mat ice battery has a better performance in terms of the evolution of the ice mass fraction as well as the amount of latent heat exchanged on an ideal operating day. We have validated the flat plate model with the experiments and are currently conducting experiments with the capillary mat heat exchangers.

At the moment, we can operate the whole test rig by remote control with the LabView program. Through this LabView program we are able to monitor, measure and control different sensors and valves. This also allows us to simulate a cooling load profile for any operation. This gives us the ability to test different cooling load profiles, different solar PV data based on different weather data, and adjust the control strategy based on different situations.

Mr. Genes, you have been on board with your company from the beginning of the project. What made you get involved and what do you specifically expect from the project?

I was impressed by the idea of putting solar energy – which has so far been produced superfluously – to good use after all. This energy is used to produce and store cold for an ice store. This has great advantages

Especially in the manufacturing industry, more and more cold is needed. I think if the project is pursued properly, there will be many people interested in the technology. The savings are compelling.”

Richard Genes, Managing Director Genes Kältetechnik GmbH

How can a company get involved here in a very practical way, and how does the university benefit, Mr. Sharma?

As a corporate partner, Genes Kältetechnik GmbH had the goal of using the combination of ice storage and chillers for refrigeration applications from the very beginning and supports us with its expertise. Since the beginning of 2020, we have been working with Mr. Genes to set up the test stand in the energy lab at the Münchberg campus. Since then, the project has already been presented at various international conferences and corresponding technical articles have been published. In the context of an Indian conference, it was awarded as the best paper of the conference.

Research is also always based on the principle of try & error: What kind of experiments are currently being carried out?

At the moment, two projects are underway with the topic of ice storage: The first project is being carried out on the ice storage test bench in the energy laboratory. On this test bench, we are testing two different types of ice batteries based on flat plate and capillary mat heat exchangers. Through the LabView software, we have the ability to implement a hardware-in-loop simulation where we can simulate different cooling load profiles and test different control strategies. We do this by controlling the flow of coolant through valves.

The second project is a collaborative project with the Swiss SPF Institute for Solar Technology at OST University, Rapperswill in Switzerland. In this project we validate the TRNSYS model with the experiments for an ice storage tank from VIESSMANN (Isocal), which is buried in the ground outside the energy laboratory. For a new set of experiments for this project, we have installed new soil temperature and ice fraction sensors to obtain more accurate results. These should help us understand the dynamics of heat transfer between the soil surrounding the ice storage tank and the water/ice in the tank. Once the icing and melting properties of the Isocal model are validated with the TRNSYS model, full system validation will be initiated.

Are there any initial results you can report?

Yes, we conducted experiments with an ice battery based on a plate heat exchanger last year. The results were also published in the conference proceedings of RETCON 2021. From the simulation point of view, some models still need to be improved to reduce the discrepancies between the experimental and simulation results.

Also in the second project, we already have some good results from the icing and melting experiments conducted earlier this year. More experiments are currently being conducted to learn even more about the icing characteristics and the heat transfer process between the ground model and the ice storage model. We hope to have some satisfactory results soon so that we can publish them in reputable journals

So where might the potential applications of the technology lie in the medium and long term, thinking about people’s everyday lives, Mr. Genes?

The use of the technology will certainly always be in the manufacturing sector. In the private sector, in the medium and long term, there could also be integration into home supply, e.g., for air conditioning in living spaces.

I hope that the university will continue to come up with such good technical ideas! I will then always accompany and support them.”

Richard Genes, Managing Director Genes Kältetechnik GmbH

The cost/benefit ratio is also always important for the feasibility of research. How does it look in this area? Can the technology become suitable for mass production in the foreseeable future?

Both the economic and energy performance of the technology have been theorized through various case studies in the Polysun and TRNSYS simulation software. Recently, an energy and cost savings analysis case study was also conducted for the traditional brewery “Meinel Bräu” in Hof. Through the performed simulation results, the payback time of the system was estimated to be about 5 years. After this payback period, significant five-digit euro amounts can be saved annually in energy costs.

What is the next step and when will the project be completed?

At the moment, we are planning a continuation project with a company that can develop a physical control system and implement our concept. We would like it to be able to be used in real time by an industrial partner in the foreseeable future. As soon as the project proposal is worked out, we will apply for project funding in the Central Innovation Program for SMEs (ZIM).