3D printing has been part of the repertoire at Hof University of Applied Sciences for years. This technology was already used with the introduction of technical courses of study at the turn of the millennium – the first machine for this was procured with funds from the sponsoring association. This was a forward-looking support for teaching. Of course, the techniques of 3D printing continue to evolve: Surprising developments and possible applications keep popping up, and the spread is large and growing. Devices for a few hundred euros are sold to hobbyists in supermarkets – on the other hand, there are manufacturing plants for the aircraft industry, which require an investment of several million euros.

However, all these technologies have one peculiarity: materials are required in a form that is almost exclusively produced for this technology. These are usually powders, filaments or liquids, which are prepared and optimized very specifically.

A wide variety of plastic granules

Of course, this is not necessarily an advantage; because materials produced for other, much more widespread processes often cannot be used. In particular, when it comes to producing plastic parts using 3D printing, plastic granules, such as those commercially available for injection molding and extrusion, offer a much wider range of types and properties than those available as powders or filaments.

New investment

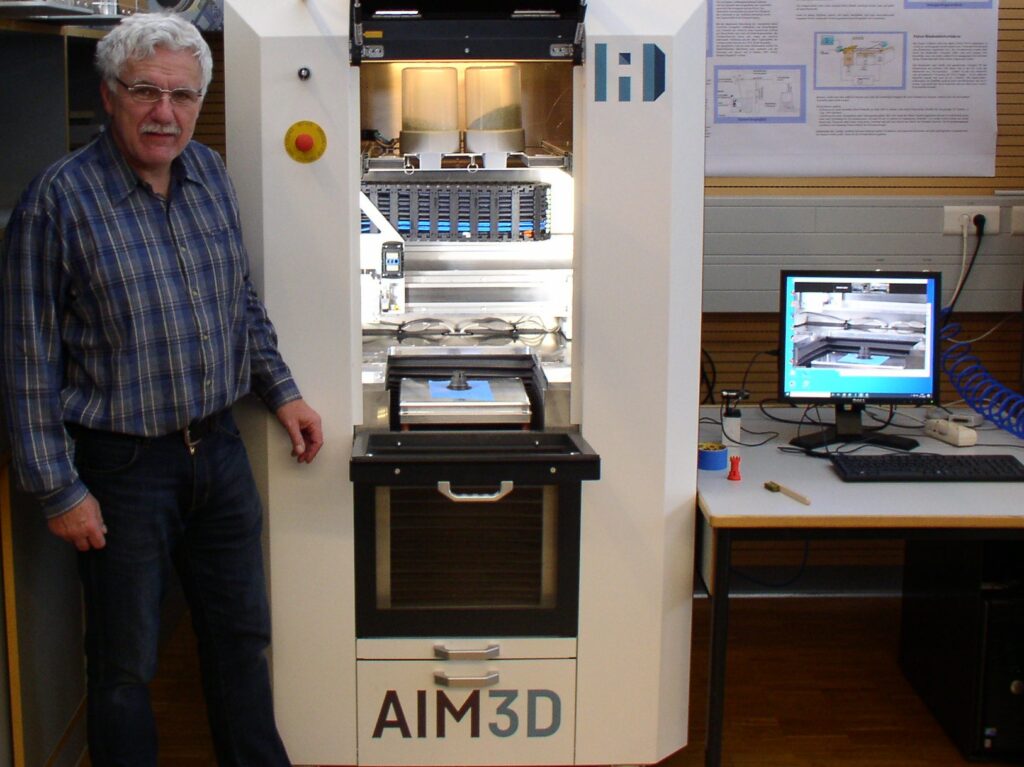

This is where a new investment by the university comes in. The university’s rapid prototyping lab is generously supported by its sponsor, Dr. Schneider Kunststoffwerke, so about half of the investment cost came from this influx. A 3D printer was purchased, which can directly print plastic granulate

Such devices are a novelty on the market. The ExAM 255 3D printer was developed by AIM 3D GmbH, a spin-off of the University of Rostock, which aims to significantly reduce the costs of additive manufacturing

We are particularly interested in the processing of plastic formulations, which so far have had little significance in 3D printing, but have a lot of potential for the future.

Prof. Dr.-Ing. Herbert Reichel

These are

- Biopolymers, also reinforced with natural fibers; a topic that is being addressed in research by the Institute for Biopolymer Research at Hof University of Applied Sciences (ibp).

- highly filled conventional polymers, which have special properties (for example conductivity or high strength)

- Granulates in which the plastic serves as a carrier matrix for ceramic or metal particles; ceramic or metal parts can be produced from these by subsequent processes.

Research activities are intended to be developed for processing such materials. Supporting startups and local SMEs with these technologies is also an approach to make good use of this investment