Starting with the winter semester 2023/24, the Master’s program “Sustainable Water Management and Engineering” offers its students a new interdisciplinary and innovative elective module: Digitized Water Management in Integrated Aquaculture (DiA).

Within the framework of the new elective module, students can familiarize themselves with the topic of digitalization in integrated aquaculture through practical and also self-determined course content.”

Prof. Dr. Manuela Wimmer, head of the Sustainable Water Management and Engineering program

The implementation of the module in the “NaLeA” project is funded by the Innovation in University Teaching Foundation, as part of the “Freiraum 2022” call for proposals.

The idea

The international master’s program “Sustainable Water Management and Engineering” is designed to train specialists for water management. It combines management and engineering skills with the topics of digitalization and sustainability. One of the central questions is how clean water can be provided worldwide to supply people and the environment. Nevertheless, the students are also expected to think outside the box. So far, they have had the opportunity to do so in lectures on “Food production in aquaculture with efficient use of resources,” among other things. Aquaculture, i.e. the controlled rearing of fish and other aquatic creatures in specific husbandry systems, has taken a liking to the study program participants. Therefore, the research group leader Dr. Harvey Harbach and study program director Prof. Dr. Manuela Wimmer have been working on offering an even more in-depth course on the production of food in water.

The NaLeA project

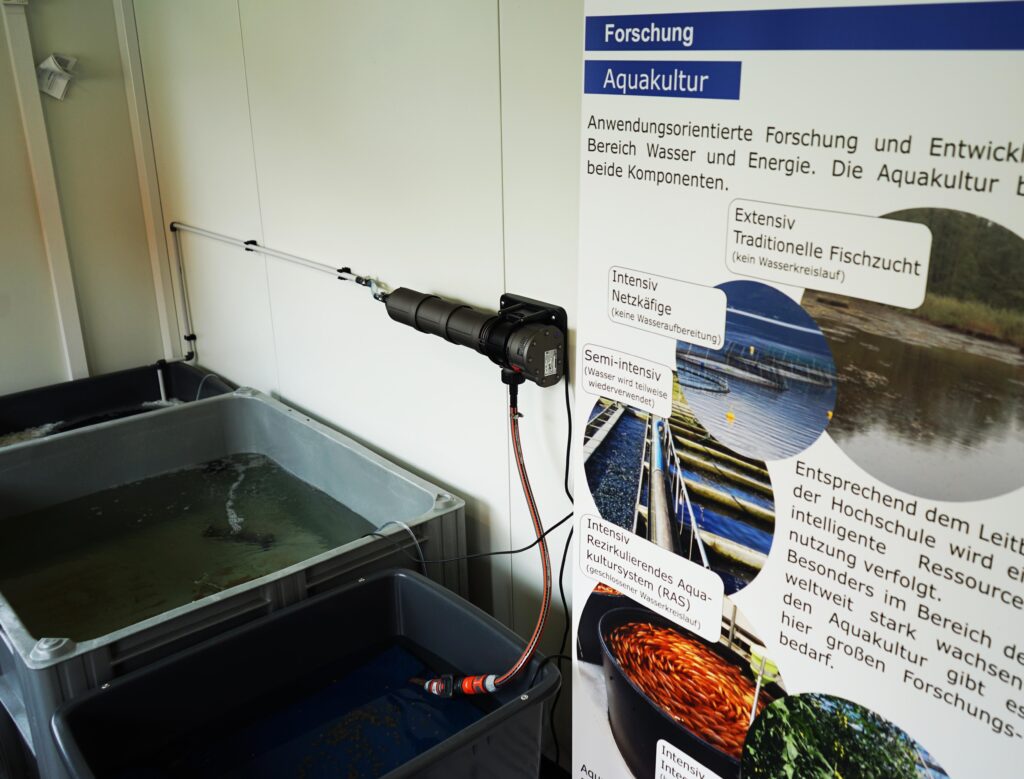

The starting signal for the associated project “Sustainable Food Production in Integrated Aquaculture” (NaLeA) was given on 01.09.2022. The foundation “Innovation in University Teaching in Sponsorship of the Toepfer Stiftung gGmbH” is funding the conceptual design and introduction of the elective module with approx. 385,000 € over two years. Its unique selling point is that the module provides deeper insights into processes in overlapping virtual reality and reality than is possible in conventional teaching concepts. Not only concepts of sustainable aquaculture are taught. On the contrary, the focus is to be on the active acquisition of methodological competence. This includes, for example, know-how for the planning and management of a plant or for the application of digital measuring and control techniques. The project will employ three scientists and six auxiliary scientists in order to be able to successfully manage the diverse tasks in the areas of organization, plant support, and interactive teaching. From the summer semester 2023, the practical project “Digitisation in Aquaculture” (DiA) will be offered in the Bachelor “Environmental Engineering”, and from the winter semester 2023/2024, the elective module “Digitised Watermanagement in integrated Aquaculture” (DiA) will be offered for the Master students.

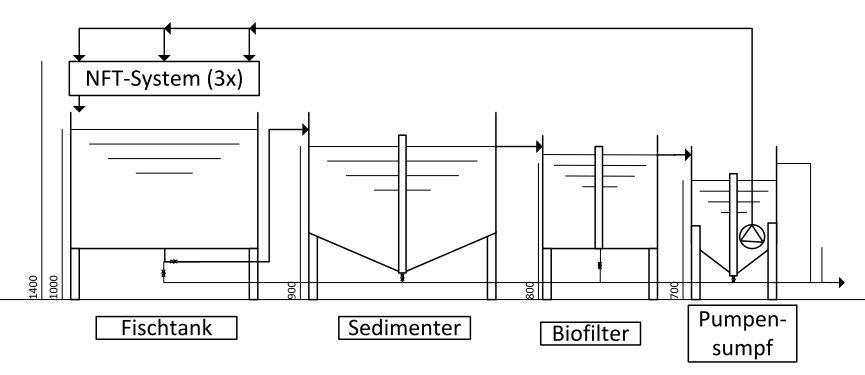

The integrated aquaculture system

“Fail fast, learn faster” – “Fail fast, learn faster”. This saying adorns the entrance area of the university and can also serve as the motto for the elective module.

The students will be given their own aquaponics system. They are free to let off steam on this model. Whether “their farm” produces food economically at the end of the semester is entirely in their hands.”

Dr. Harvey Harbach, head of the Resource Efficient Food Production in Integrated Aquaculture research group

An aquaponics facility is the perfect research and application object for this, because it integrates the keeping of fish (aquaculture) with the production of vegetables or other plants in a nutrient solution (hydro-ponics). This implies that a circuit is formed from both systems, in which the water is circulated and recycled. Thus, water consumption for the production of plant and animal food is reduced. Of course, the issue of energy as well as efficiency will also be considered.

Specifically, the wastewater from the fish tanks is first mechanically filtered to remove feed residues and feces. This is followed by a so-called biofilter, in which the ammonia excreted by the fish, a cell toxin, is converted to nitrate by beneficial bacteria. This is a binding form of nitrogen that plants need to grow and form fruits. The nutrient-rich water is directed to the plants. These act as filters, removing the nitrate as well as phosphorus and other nutrients from the water. Then the purified water is returned to the fish. They can eat and grow well in it – and in the process release more nutrients into the water. The circle is closed.

Nutrient recycling in human-influenced systems and its impact on the environment is one of the core topics in the master’s program.”

Prof. Dr. Dr. h.c. Jürgen Lehmann, President of Hof University of Applied Sciences

“I am therefore pleased that the students are confronted with this challenge in a real aquaponics plant. They will be able to use the principles and solutions they have acquired not only in the field of integrated food production in water, but also, for example, in municipal wastewater treatment,” President Lehmann continued.

Teaching reinterpreted

In the elective module, students actively take on the roles of plant operators, investors, planning authorities, representatives of public authorities, building contractors and manufacturers of plant components and the associated measurement and control technology. After a clear but necessary theoretical part, the participants will prepare a business plan. There should be no guidelines for this.

Which type of fish is to be produced, which components are to be used in the plant and on what scale, which plants are to be cultivated, or to whom and where the food is to be marketed – the student team is allowed to research and determine all of this themselves. Whether that is then supported by investors and approved by the authorities is another question.”

Lena Bächer, research assistant

The semi-virtual concept makes this realistic approach possible. Subsequently, the planned aquaponics plant will be set up on a reduced scale at Hof University of Applied Sciences. The plant will serve as a model to be able to investigate and control nutrient flows – and to do so online.

Digitization of food production

One auxiliary tool that will make this possible is digital measurement and control technology. The well-being and thus growth of the imaginary fish and plants depends primarily on the quality of their common water. Therefore, this is to be continuously investigated. The students are again responsible for this. They will install and program the measuring probes for nutrients, the mini-computers and the control units themselves. It is also their task to process the measured values obtained from remote monitoring and to draw practical conclusions from them. The findings from the independent, data-based optimization of the process control or the entire plant setup can be transferred to other areas of water management.

Graduates of the DiA module will, on the one hand, have gained a sound understanding of nutrient fluxes in water. On the other hand, they will also have the practical ability to control nutrient fluxes using digital tools. Whether they later successfully produce fish and vegetables for the local food supply or optimize wastewater treatment processes in such a way that ecosystems are relieved and water consumption is reduced is up to them. Without question, however, any region that can count on such skilled workers will benefit.”

Dr. Harvey Harbach