Will we soon be sitting on antibacterial seats on the bus or train? An exciting research project with topical relevance and a wide range of possible applications is currently underway at Hof University of Applied Sciences: At the Institute for Materials Science (ifm), research is being conducted into antibacterial surface coatings. In the future, these paint compounds are to be used in particular in hospitals, doctors’ surgeries or even in public transport and inhibit the spread of bacteria and viruses. For the first time, a natural substance that can be obtained from fishery waste, which has been little used until now, is expected to help.

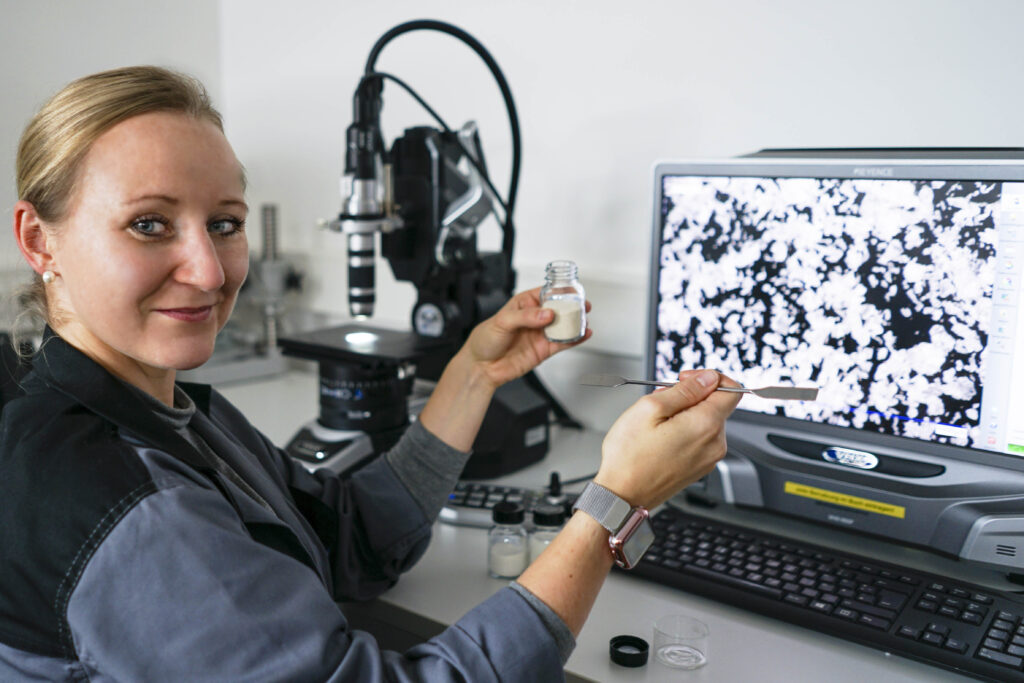

Jessica Wittmann (31) is a research associate in the “Hospital Bed” research project at Hof University of Applied Sciences. Together with two colleagues, the industrial mechanic with a focus on materials engineering, who also holds a master’s degree in applied surface and materials science, has set herself the task of actively researching a problem that is currently on everyone’s lips worldwide: With the help of novel paint coatings, the Hof researchers want to inhibit the spread of bacteria and viruses on surfaces – and this especially in highly frequented and therefore hygienically particularly critical places. Despite the name of the project, hospital beds are only one of many possible applications.

Using the effect of natural raw materials

“It is true that there are already coatings that have an antibacterial effect. However, these contain substances that are heavily criticized for their effect on humans – think, for example, of coatings containing nano-silver. We want to replace these substances with skin-friendly natural raw materials. And ideally with the same or even better effect,” says Jessica Wittmann, explaining her research approach.

The power of white powder

A very special substance that has so far been found in some tooth-cleaning products, pesticides and medical products is expected to help: Chitosan. The natural biopolymer is found in the shells of crustaceans and can have antimicrobial, antibacterial and antiviral effects. Extracted from fishery waste in a multi-step process, it reaches the Hofer laboratory in the form of a white powder. The right processes for further processing, the correct dosage and, last but not least, the best possible incorporation into the surface coating are then what Jessica Wittmann and her colleagues are concerned with in the course of many test series. In the process, the researchers are still dealing with a whole series of unknowns:

Question of the right dosage

“We don’t yet know: does chitosan work best as a powder, in particle form or dissolved in some other way? It is also unclear which dosage will be sufficient to ultimately achieve the best possible antibacterial effect,” says Wittmann, who worked for four years in the development department of a well-known polymer specialist from Upper Franconia before joining Hof University.

Image: Hof University of Applied Sciences

The question of dosage, i.e. how much chitosan is needed per square meter of surface, may ultimately also determine whether the finished product actually finds its way into everyday use in hospitals, doctors’ offices or buses – after all, the process of extracting the substance is quite complex and therefore expensive. So far, there are no empirical values, because the incorporation of chitosan into coating materials is still in its infancy

We are hopeful that it will be able to develop its known effect even in relatively small concentrations, so that industrial use will be possible at a later stage.

Jessica Wittmann

“However, we have hope that it will be able to develop its known effect even in relatively small concentrations, so that industrial use will be possible later,” Jessica Wittmann says optimistically.

Image: Hof University of Applied Sciences

The research project is scheduled to be completed by mid-2022. It is under the technical direction of Prof. Dr. Jörg Krumeich, who is responsible for the Materials and Surface Engineering department in the Faculty of Engineering at Hof University of Applied Sciences. It is funded by the Central Innovation Program for SMEs (ZIM). The industrial partner in the project is lacolor Lackfabrikation GmbH, an experienced company in the sector.