Ms. Wittmann, first of all, congratulations on this year’s Special Research Award, which the Society of Friends and Sponsors of Hof University of Applied Sciences presented to you at the end of April. What will you do with the prize money?

Thank you very much for your congratulations. We are very pleased to have been awarded the Special Research Prize. The €10,000 prize, which was offered for the first time in 2021, is a great honor for the entire project team and pays special tribute to both the research at Hof University of Applied Sciences or at the Institute of Materials Science (ifm) and the project-related collaboration with the company Lacolor Lackfabrikation GmbH from Enger (NRW). We do not yet have any set plans for what we would like to use the prize money for, but we have several ideas. We would like to invest in bio-based specialty raw materials. Particularly modified types, such as special chitosan with adjusted molecular mass, are comparatively cost-intensive to purchase in small quantities. Furthermore, we intend to use the prize money, if necessary, for some additional, special characterization methods that are not available at HAW Hof or at ifm. Furthermore, we can imagine that part of the prize money will be used for trade fairs or technical literature.

Since 2020, you have been researching an unusual idea: using the fisheries waste chitosan, you want to arm surfaces against viruses and bacteria and inhibit the spread of pathogens. So are we already lying in such a coated bed during a future hospital stay, or will we soon be riding in a bus whose seats are virtually free of viruses and bacteria?

Both ideas are very nice and would definitely make tomorrow’s world a bit better. Unfortunately, however, it is not as simple as this idea sounds in practice. Once we have managed to develop a durable and effective coating, every application is still subject to normative requirements and regulations. In the case of our hospital bed example, the Robert Koch Institute (RKI) would have to give its approval for a specific application in hospitals. Without the corresponding approval of the RKI, hospitals or hospital operators are not allowed to change the equipment features on their own. In this case, our antimicrobial bio-coating can therefore only be used after approval by the RKI. For the application in the bus, it would also have to be clarified in advance which standards and guidelines have to be complied with. Provided that our developed coating would meet all requirements for the bus application, it may indeed happen that soon add-on parts in the bus are provided with our coating.

Where could the chitosan paint compounds be used everywhere in the future?

In principle, the paint compounds could be used on any surface that is coated in any way. The antimicrobial chitosan coating can be used in a variety of ways while complying with normative requirements and regulations, including, for example, on public transportation, in buses and trains, in libraries, in offices, in counter and bar areas, and wherever there is a high risk of infection due to a high volume of public traffic.

Where did the idea for your research project come from?

The project idea came about in retrospect, like many developments: Making tomorrow’s world a little better through today’s developments. Topics such as environmental pollution, resource conservation, germ contamination, use of bio raw materials from nature, sustainability and circular economy or recycling of waste are major motivating factors that contributed to this research. Furthermore, the project idea is characterized by reducing the use of previous substances such as silver, silver (nano) particles or copper and substituting them with bio-based agents. This could prevent additional environmental pollution, since possible degradation of the coating may involve the risk of uncontrolled release of silver or copper particles into the environment.

How can our readers imagine a typical working day in the laboratory?

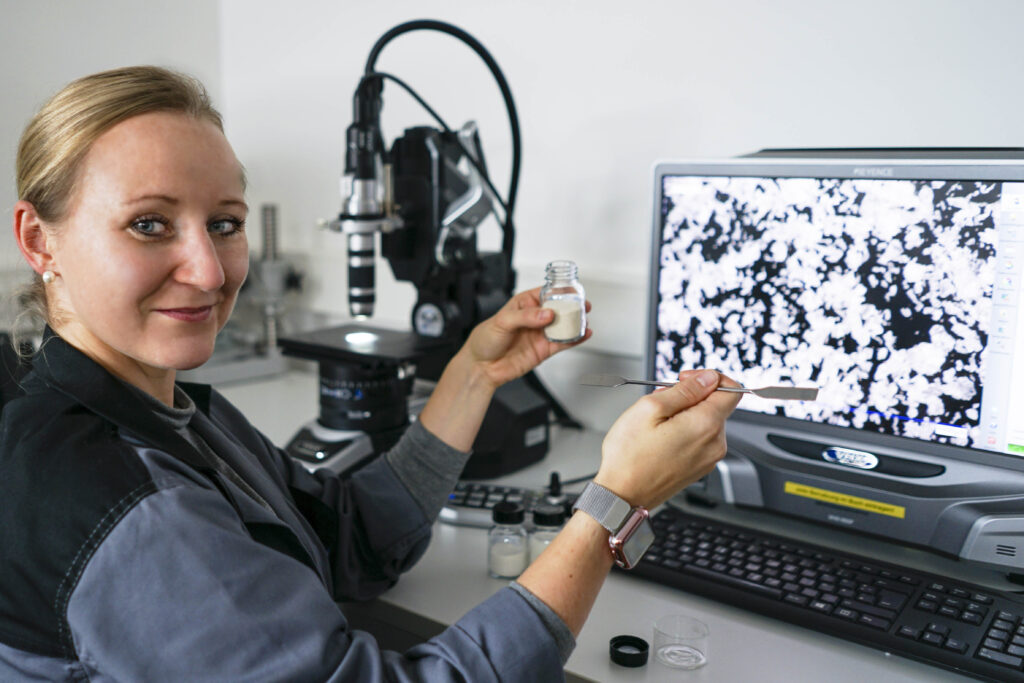

There is rarely a typical working day as such in research. But if I were to describe a typical lab day, it would start with an agreement on the next steps with the project partner, from which an experimental plan is drawn up. According to this plan, the project partner mixes the specified coating formulations and produces the sample plates. This clearly defines which combinations of coating materials and formulations are to be used. If coated and dried samples are already available, I prepare them for various tests. In particular, I often determine the dry coating film thickness, look at the coating surface with a light microscope, determine the line and surface roughness, test the coating for chemical and scratch resistance, prepare the samples for external testing of antimicrobial effectiveness, and much more. Afterwards, I evaluate the results and discuss them in the project team. Depending on the results, we then discuss which optimization steps to pursue next and why. In parallel, we always compare the results with the relevant literature in order to verify the results or to build on existing research work. In addition to these main tasks, there are many other activities, which means that the typical day in the lab is always exciting in its own way.

Your research project is funded by the German Federal Ministry for Economic Affairs and Energy and should be completed by the end of September this year. What is the next step?

Yes, the “KH Bett” research project will run up to and including September 2022. Since we found out during the processing that the potential for biobased active substances is very large, we are very interested in follow-up projects. If it can be realized, we would like to conduct joint research with our existing project partner lacolor Lackfabrikation GmbH on further development as well as vertical and horizontal scaling. We are already working on project proposals that we would like to submit in the near future. We are very pleased if the current funding opportunities give us the chance to further advance research into biobased active ingredients in coating formulations and thus provide added value for the environment and the economy.

Thank you very much for the interview!