The MakerSpace in the C-building at Hof University of Applied Sciences is a professional workshop with high-tech machines, tools and software. It is a place where tinkerers can develop and let off steam creatively and with their hands. The Makerspace, with all its equipment, is open to all students and employees of Hof University of Applied Sciences.

All interested parties have the opportunity to try out and discover existing technology in the MakerSpace. In an interview with René Göhring, the project engineer of the MakerSpace, and student employee Lea Schmidt, we from Campuls.digital introduce the high-tech workshop at Hof University of Applied Sciences in more detail.

Mr. Göhring, how did the MakerSpace or the idea for it come about?

René Göhring: The original idea was brought to Hof by our Dean of the Faculty of Engineering, Prof. Anke Müller. In her previous area of activity and environment, something similar already existed as an open meeting area for students. This inspiration, in combination with the StartUpLab project, was the cornerstone.

What machines are available to students and employees in the MakerSpace?

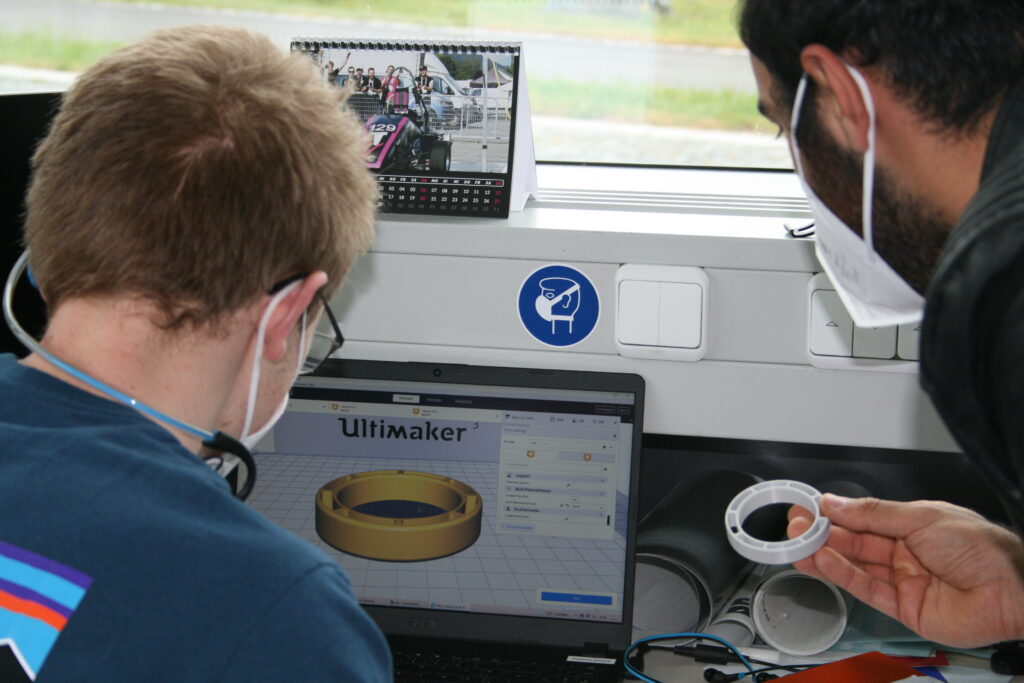

René Göhring: We now offer a wide range of equipment and tools. This ranges from simple hand tools such as wrenches, hot glue guns and soldering stations to cutting plotters, laser cutters and the small and large 3D printers. Our latest acquisitions are the VR glasses from Oculus, the 3D scanner from Shining 3D, and our Apple Ipad’s.

As the project engineer of the MakerSpace, you certainly have a favorite machine, don’t you?

René Göhring: I really like all the machines here. But if I think about it carefully, our BigRep is very slightly ahead. This large-format printer is a unique selling point here in the region. The size of the models that can be produced never ceases to fascinate me.

Ms. Schmidt, you are a student employee at the MakerSpace. How did you become aware of the project?

Lea Schmidt: I first heard about the MakerSpace in the summer of 2020, through the student association HofSpannung Motorsport e.V., and at the beginning I couldn’t believe that the project really existed. The opportunities available to students here are really something special.

What do you appreciate most about the MakerSpace, especially from the students’ point of view?

Lea Schmidt: I really appreciate that anyone can just drop by here and try their hand at creativity and crafts in a relaxed environment. It’s okay to make mistakes here, and anyone who needs help with their project will get it. From the students’ point of view, the great flexibility is definitely worth mentioning. Due to the extended opening hours, Tuesday and Thursday, it is possible to work on individual projects not only at any time of the day, but also late in the evening or at night. And should a project be more difficult to implement than expected, it is always possible to switch to another process or to work out an alternative solution with the help of the staff.

How has the Corona pandemic affected the project and how has the MakerSpace developed in recent months?

René Göhring: Despite the pandemic, we were able to carry out a great many projects. Not only online events like “Girls and Technology” via zoom, but also appointments with small groups were held.

Due to the good utilization of our 3D printers, further investments were made in this direction and even more printers were purchased. This has given us some relaxation in the allocation of printing appointments.

What else is there to see/experience in the MakerSpace? And what makes it so special for students in particular?

René Göhring: A visit to the MakerSpace is always worthwhile. There are always new projects to see. And if there was no inspiration, there is at least always a coffee or tea for a casual exchange to spin ideas for the next project.

Lea Schmidt: That’s right, our coffee machine really makes an important contribution here. What’s also special is that students from a wide variety of faculties and different projects come together and can exchange ideas in a great atmosphere. But the many opportunities to develop and try things out also provide opportunities for many.

What has been your most exciting project/your biggest challenge in the MakerSpace so far?

René Göhring: Here in the MakerSpace, every device or machine has its exciting projects and challenges. For our BigRep, this was a surface relief for the museum in Kronach. And for our lasercutter, the attempt to laser mark a smoked trout. With success, of course, and without affecting the taste.

Lea Schmidt: In cooperation with “AR-Experts”, we introduced the Giri app in the Makerspace in spring 2021. The app can create innovative step-by-step instructions in just a few minutes, supported by “augmented reality”. I was able to get the app up and running in our space and create instructions for our various machines, which have since made instructing and teaching visitors much easier. Even without assistance, proper use of the machine can be ensured in a matter of minutes without any extra effort. We also see the way Giri operates as innovation and a big step towards digitalization and are proud to be a part of it.

What is the “Students Working Kit” all about?

René Göhring: This is a small project from the MakerSpace for our students. The Students Working Kit (SWK) is a tool rolly that students can borrow from us here. It contains, among other things, an impact drill, a cross laser, saw, screws, dowels and cordless screwdriver. Everything that is needed at home or in the shared apartment, when moving in or for renovation work.

How can interested parties get in touch?

René Göhring: Just send an email to rene.goehring@hof-university.de, call09281 / 409 4681 or preferably come by in person at the MakerSpace in the C-Building at Hof University of Applied Sciences. We are looking forward to meeting you.