A new circular needling machine improves the properties of fiber composite structures and makes them usable for aerospace applications

In hardly any other field are such high demands placed on the materials used as in aerospace. Not only do they have to be very light, but also extremely strong and resistant. This applies in particular to the support structures made of tubular rods used there

Ceramic matrix composites (CMCs) do meet these requirements, but their widespread use has so far been limited by two major factors: on the one hand, by high material and production costs, and on the other hand, by the inadequate availability of suitable textile preforms as basic components. The latter in turn automatically leads to a limitation of the achievable properties of the end products, i.e. the finished CMCs.

Tubular structures for space travel

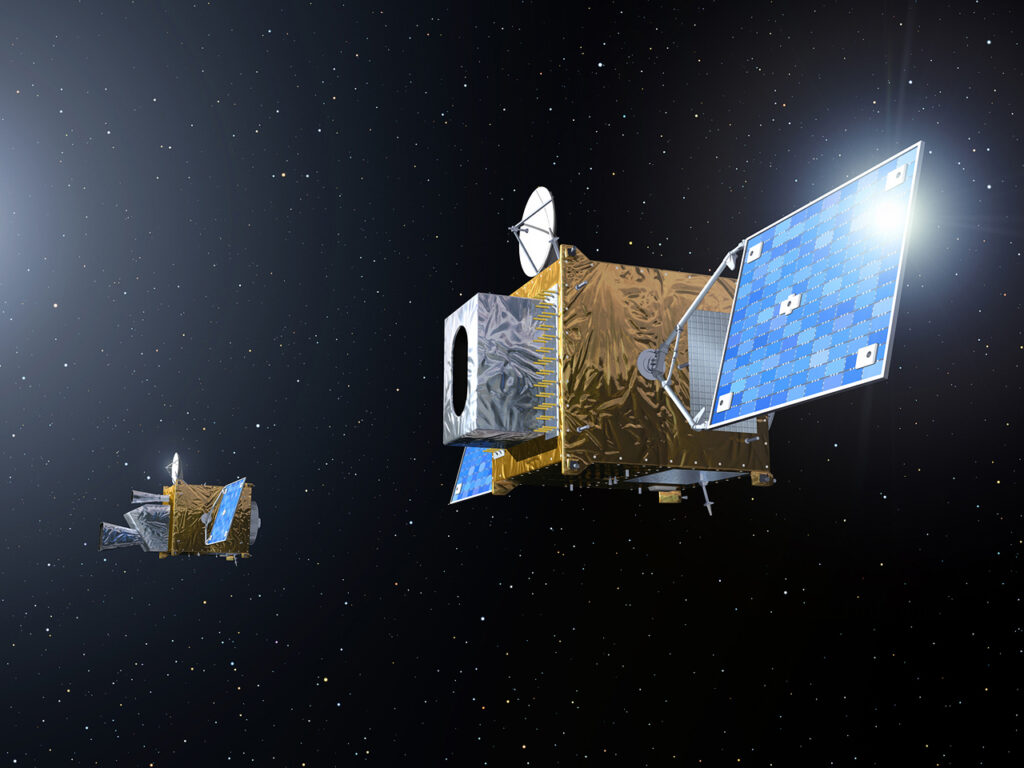

The Innovative Textiles Research Group at the Münchberg Campus has therefore now launched the research project “Circular needled C/SiC tubular structures for space travel”, or “RuRoRa” for short. The aim is to research hollow cylindrical preforms made of carbon fibers and their further processing into carbon fiber-reinforced silicon carbide (C/SiC) tubes, which in turn can be used in the form of linkage structures in satellite technology.

A new circular needling machine is currently being purchased for this purpose at the Münchberg campus, which can process textile preforms made of carbon fibers into round, endless hollow cylinders

The machine can be used to produce different diameters and wall thicknesses of the cylindrical structures. During circular needling, fibers are deflected in such a way that product strengths can be increased compared to the current state of the art.

Weight savings for higher efficiency

Due to the variation possibilities of the textile precursors that can be used in this process (e.g. scrims, nonwovens, roving, etc.), the properties, such as structure density and fiber preferences, can be specifically adjusted. The end result is material and weight savings and thus increased efficiency.

Another aim of the work is to develop a resin infiltration process that ensures damage-resistant downstream processing while maintaining homogeneity of the fiber-matrix distribution.

With the help of the innovative structures made of round-needled preforms and their further processing into solid tubes, it is intended, for example, to achieve the requirement of low thermal expansion of the mirror and measurement equipment mounts on satellites on the sun and night side in orbit.

In this way, optimal signal transmission between earth and satellites can be ensured for the satellites.

The successful development of such a structural material for linkages and mounts will facilitate access to tenders in the NewSpace sector. As larger quantities are predicted in the future space sector, the developed process provides a significant milestone for the economical production of such linkages and thus for a diversification of the fields of application.

Alexandra Luft, research group leader at the Institute of Materials Science (ifm)

Source: https://www.fe-lexikon.info/lexikon-l.htm

The “RuRoRa” project is being implemented together with the company ECM – Engineered Ceramic Materials GmbH, Tenowo GmbH in Hof as an associated partner and the Fraunhofer Application Center Textile Fiber Ceramics in Münchberg.